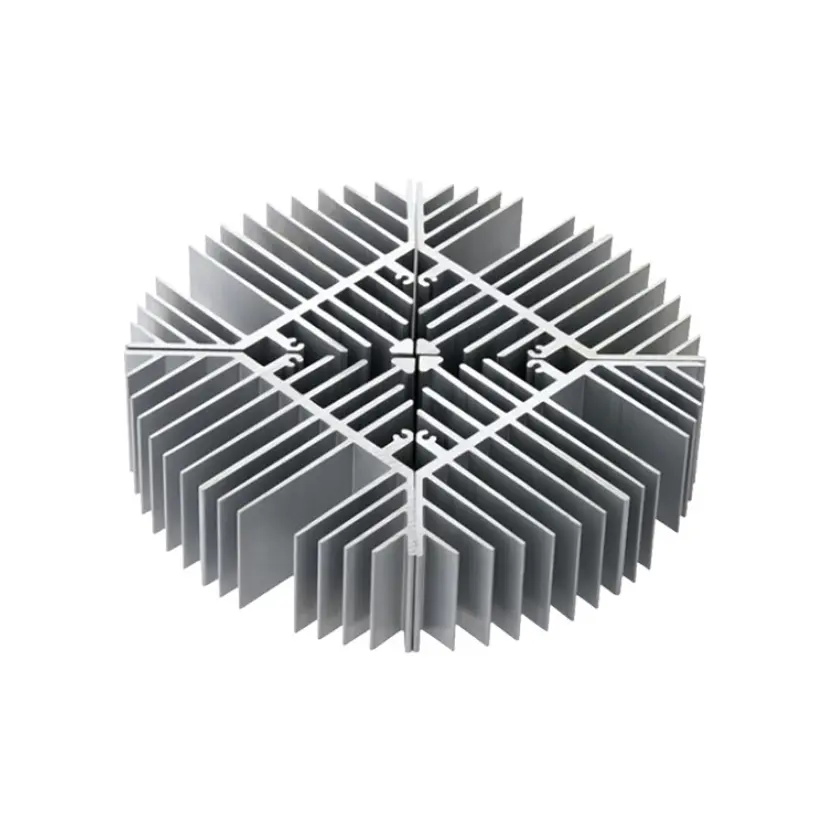

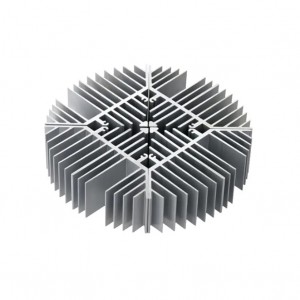

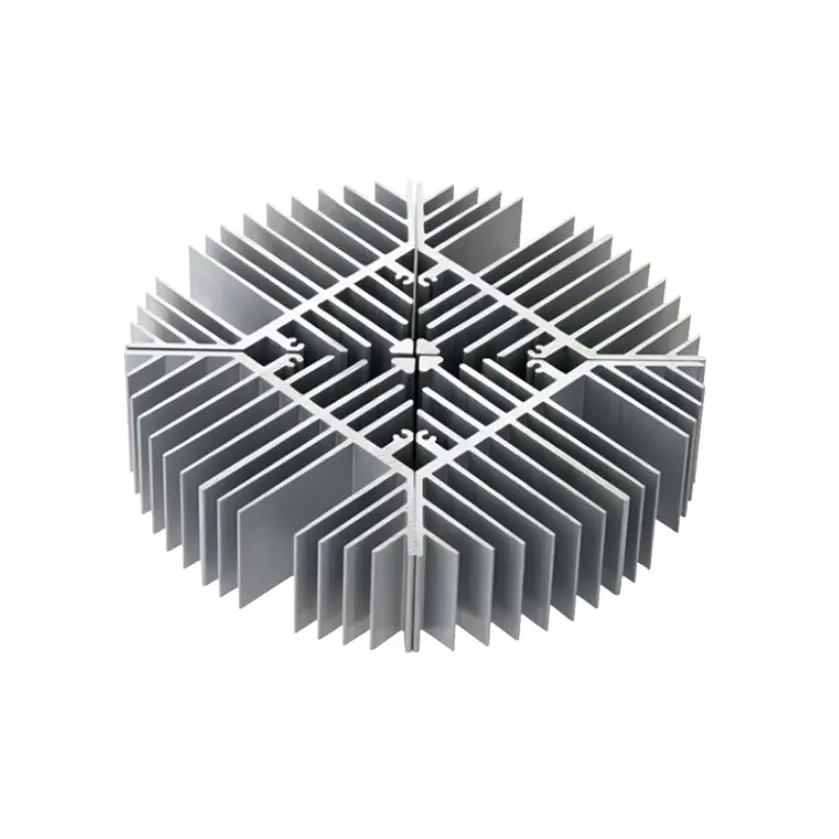

Power Supply Inverter Aluminum Led Pcb Heat Sink

adjustable ipad stand, tablet stand holders。

About This Item

1.Multiple Manufacturing Methods:

The aluminum heat sink radiator for power inverters and LED PCBs is manufactured using various processing techniques such as extrusion, die casting, and forging. Each method brings unique advantages to the product.

2.Outstanding Heat Dissipation:

This heat sink radiator is specifically designed to effectively dissipate heat generated by power inverters and LED PCBs. With a large surface area and intricate fin design, it maximizes heat transfer, ensuring optimal cooling performance and prolonging the lifespan of electronic components.

3.Lightweight and Space-saving:

Thanks to advanced manufacturing processes, the heat sink radiator achieves a lightweight and compact design. This not only reduces the overall weight and size of the system but also enhances portability and facilitates easy installation.

4. Customization and Integration:

The heat sink radiator can be customized and seamlessly integrated with other components of power inverters and LED PCBs. This flexibility ensures compatibility with different device designs and allows for efficient heat management in various applications.

Product Parameter

| Delivery Time | 15-21 days | Product name | Power Supply Inverter Aluminum Led Pcb Heat Sink | ||

| Temper | T3-T8 | Material | Alloy 6063/6061/6005/6060/7075T5/T6 | ||

| Application | Electronic | Temper | T3-T8 | ||

| Shape | Flat | Deep processing | Turning,milling,drilling,punching,bending,welding | ||

| Alloy Or Not | Is Alloy | Surface treament | Anodizing,powder coating,brushed,polishing and so on | ||

| Model Number | HBMD-SRQ02 | Service | OEM&ODM service | ||

| Processing Service | Bending, Decoiling, Welding, Punching, Cutting, turning, milling, lathe | Application | Electronic | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-100 | 101-200 | 201 - 500 | > 500 |

| Lead time (days) | 7 | 10 | 15 | To be negotiated | |

Product Display

Production