Ibhulokhi ye-heatsink yamanzi e-aluminium yokupholisa amanzi

i-ipad stand eshintshwayo, izibambi zethebhulethi.

Mayelana Nale Nto

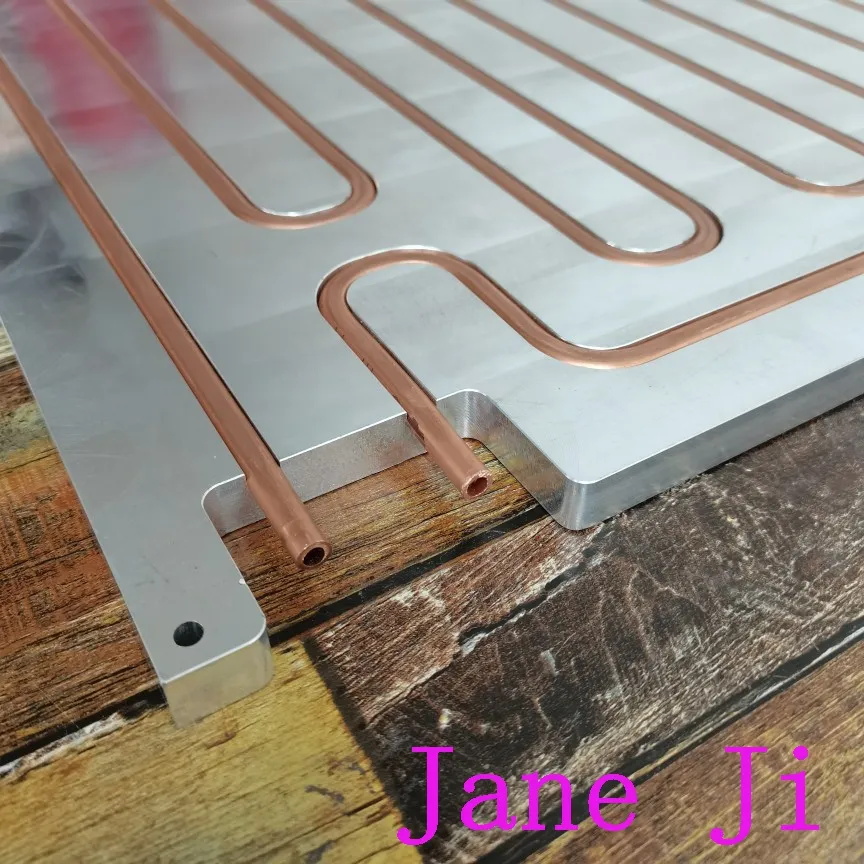

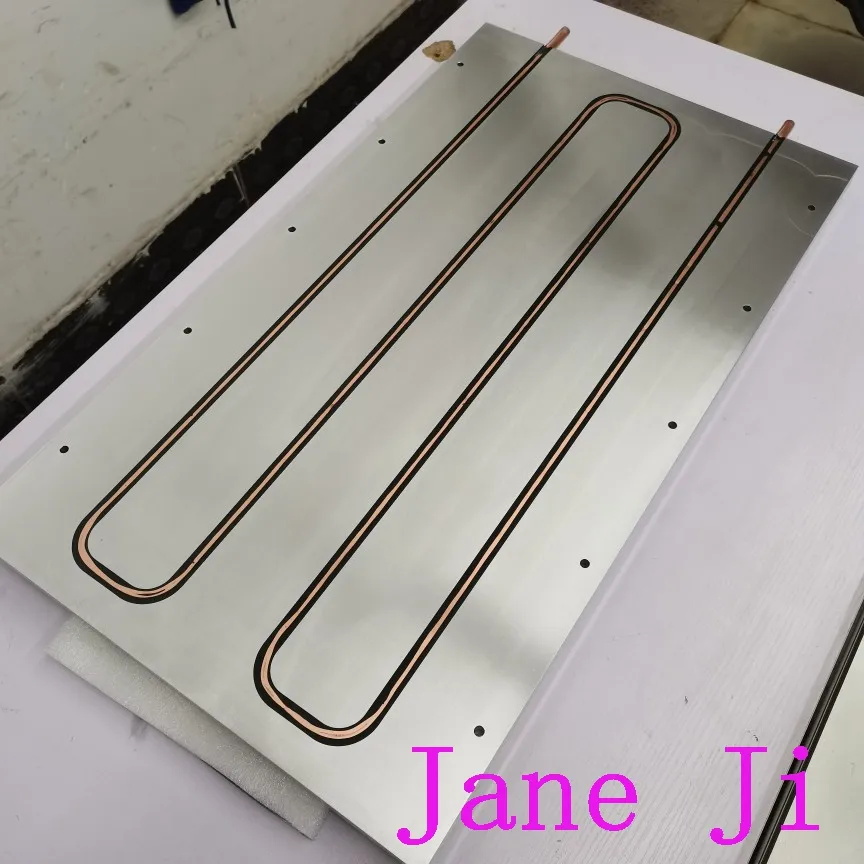

Irediyetha yepayipi lokushisa yethusi elihlanganiswe nesinki yokushisa yepuleti epholile ye-aluminium epholise amanzi iyisixazululo esisebenzayo sokupholisa esinezinzuzo eziningi.Okulandelayo yisingeniso sezinzuzo zako eziyinhloko:

1.I-thermal conductivity ephezulu:

I-Copper iyinto enhle kakhulu ye-thermal conductivity ene-conductivity enhle kakhulu ye-thermal.Ipayipi lokushisa lethusi lingakwazi ukumunca ngokushesha futhi liqhube ukushisa okukhiqizwa okokusebenza, kuyilapho i-aluminium epholisa amanzi epuleti lokushisa ibhulokhi ingakhipha ukushisa ngokuphumelelayo, okwenza umphumela wokukhipha ukushisa ube ngcono nakakhulu.

2. Ukusebenza okunamandla kokukhipha ukushisa:

ipayipi yokushisa yethusi inikeza indawo enkulu yokukhipha ukushisa, kuhlanganiswe nesakhiwo esiyingqayizivele sokukhipha ukushisa kwe-aluminium amanzi-cooled plate heat dissipation block, ingathuthukisa kakhulu ukusebenza kahle kokukhipha ukushisa.Bangakwazi ukuqhuba ngokushesha futhi bachithe ukushisa okuvela ezingxenyeni zokushisa okuphezulu, ngaleyo ndlela banciphise ngempumelelo izinga lokushisa lemishini.

3.Ingasindi futhi ihlala isikhathi eside:

Uma kuqhathaniswa nezinye izinto (ezifana nezimpiko zokupholisa zethusi), ibhulokhi yokupholisa ipuleti le-aluminiyamu yamanzi ilula futhi ngeke ibangele umthwalo owedlulele kumpahla.Impahla yethusi inokumelana nokugqwala okuhle nokuqina, futhi ingagcina ukusebenza okuzinzile kwe-radiator isikhathi eside.

4. Ukonga amandla kanye nokuvikelwa kwemvelo:

i-radiator yepayipi lokushisa lethusi kanye ne-aluminium yamanzi epholisa ipuleti lokupholisa ukushisa zisebenzisa amanzi njengendawo yokudlulisa ukushisa.Uma kuqhathaniswa nendlela evamile yokukhipha ukushisa kwabalandeli, ingamunca futhi ikhiphe ukushisa ngempumelelo kakhudlwana futhi yehlise ukusetshenziswa kwamandla.Ngesikhathi esifanayo, ngeke zikhiqize umsindo nokungcoliswa komoya, futhi zinobungane kakhulu emvelweni.

5. Ukufakwa okuguquguqukayo:

Kokubili irediyetha yamapayipi okushisa ekhopha kanye nebhulokhi yokupholisa ipuleti le-aluminium epholile ngamanzi zisebenzisa idizayini eyimojula, okulula ukuyihlakaza nokuyifaka.Usayizi wabo omncane uvumelana nezingqinamba zesikhala semishini ehlukahlukene futhi kulula kakhulu ukuyisebenzisa.

Ipharamitha Yomkhiqizo

| Uhlobo | Izingxenye Zokushintsha Ukushisa | Umbiko Wokuhlolwa Kwemishini | Kuhlinzekiwe | ||

| Isicelo | Izingxenye Zokuqandisa | Isimo | Okusha | ||

| Izimboni Ezisebenzayo | Izitolo Zezinto Zokwakha, Izitolo Zokukhanda Imishini, Imboni Yokukhiqiza, Imisebenzi Yokwakha, Amandla Nezimayini, Okunye | I gama le-brand | I-Aluminium W2 | ||

| Indawo ye-Showroom | Lutho | Igama lomkhiqizo | aluminium amanzi okupholisa ipuleti heatsink block | ||

| Okubalulekile | I-Aluminium +Copper Tube | Qeda | I-Mill Finish, Ipholishiwe | ||

| Umbala | Imvelo | Inqubo | I-CNC Milling+ Friction Stir Welding | ||

| Ukubekezelelana | +/-0.01mm | Isevisi | ODM OEM | ||

| Ukuhlola okuphumayo kwevidiyo | Kuhlinzekiwe | Usayizi | Ngokwezifiso & Isitoko | ||

| Isikhathi sokuhola:Inani lesikhathi kusuka ekubekweni kwe-oda kuya ekuthunyelweni | Ubuningi (izingcezu) | 1-500 | 5001 - 10000 | 10001 - 20000 | > 20000 |

| Isikhathi sokuhola (izinsuku) | 15 | 30 | 30 | Kuzoxoxiswana | |

Isibonisi somkhiqizo

Ukukhiqiza